Grease Inteceptor Pumping & Cleaning Service

Toll Free: 888-800-0118

Providing Great Prices and High Service Quality Since 1988

Grease Interceptor

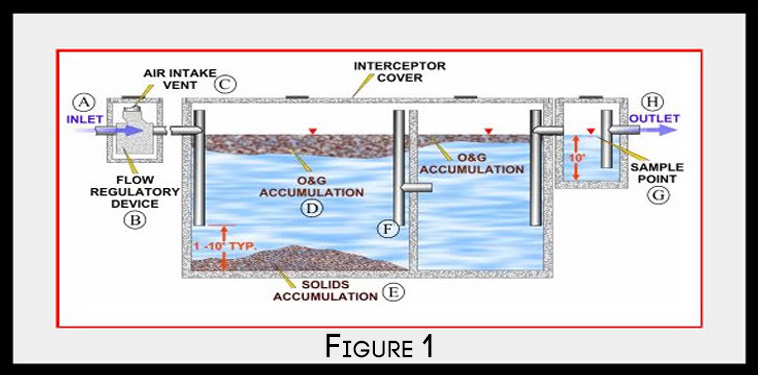

Grease interceptor (GI) is a plumbing device that is designed to eliminate fats, oils, grease and solids from entering the city sanitary system. Sizes of grease interceptor can vary with a minimum size of 750 gallons and due to its large size it is located outside the premises. Grease and Solid waste entering the grease interceptor will mainly come from the kitchen; no sanitary waste should ever enter this system unless there is a plumbing problem. Grease interceptors are efficient when grease and solid content level of 30% or below. Once it goes over tha level it starts to release higher amount of grease and solids to the main or city sewer. Hence, when running efficiently grease interceptors can trap up to 80-85% of grease and solids. Therefore, there are still a large percentile of grease and solids that escape out of the GI. Since there are still a percentage of grease being released, in order to maintain the lines from blockage it is highly suggested for the grease lines to be hydro jetted every 6-12 months. Failing to properly maintain the lines can lead to grease interceptor overflow or line blockage.

Pumping &Cleaning process

Serving Southern, California Since 1988

Grease interceptor can have one or more chambers and manholes. When pumping the interceptor we remove all the lids and pump from the top until it is completely empty. Please note that in order to properly service a grease interceptor, all content must be removed from top to bottom. Since grease interceptor contains grease, water and solids (See Picture Below Figure 1), the servicer must pump out the grease and water in order to reach the solids in the bottom. Please note that many companies will try to lead customers in they have lower prices but in actuality they only skim the grease on the top of the interceptor. As an example, if you have 1,000 grease interceptor that is being maintained quarterly with 20% grease and 15% solid content; they will only take out the 20% grease leaving 800 gallons inside the interceptor. Keep in mind that the fact that solids is heavier that both grease and water, it settles in the bottom and over time it can solidify and be very costly to remove. At JR Grease Services, Inc. we will ensure you that the grease pumping service we provide will be a complete pumping at all times. We pledge to not take any shortcuts that can negatively affect our customers in the long run.

Is my grease interceptor full?

Call us to get pricing on a grease interceptor pumping service today.

When a grease interceptor is 750, 1,000, 1500, 2,000, 2,500, 3,000, 3,500, 4,000, 4,500, 5,000, etc. gallons, this means that in normal working condition it must have that constant amount all times; unless there is a blockage. Grease interceptors are only empty when it’s new or the day when it’s pump out because in order for the device to separate FOGS (Fats, Oils, Grease, and Solids), the water that acts like a separator. Once it arrives at its maximum capacity, for every liquid that it takes in, it releases the same amount out to the lateral or the city sewer lines. Therefore, a grease interceptor should always be filled whether it’s with only water or with a combination of grease, water and solids. To determine if the interceptor is needed to be serviced, a manifest has to be sampled to count the grease and solids content. Please note that grease interceptor is not supposed to be a 100% filled up with grease and solids. Rather, once the interceptor reaches a capacity of 30% of grease and/or solids content, it is required by the county sanitation district for the device to be pumped out.

We focus on providing a long term solution and pledge not to take any short cuts.

JR Grease Services